Mining Pump Condition Monitoring System

Industrial Internet of Things IIoT is the application of IoT to the manufacturing Industry. “70% of Mining businesses say IIoT is essential to gaining a competitive edge.” Mining industry stands to make some strategic gains when it integrates IIoT applications into operations. This is because the Industry is extremely competitive due to the scarcity of resources especially labor resources. Such scarcity becomes even more pronounced in developed countries where labor charges are significantly higher than in developing countries. Automation of processes and improved asset utilization due to IIoT integration lead to optimum utilization of resources that ultimately leads to lower operating cost. Mining firms which produce the same output through minimum factor cost can make higher profit margins.

Since Pumps constitute a considerable chunk of mining operations, we would like to emphasize on how IIoT software can help improve mining pumps to give significant benefits. Mines utilizes a wide variety of Pumps such as centrifugal pumps, Slurry pumps, submersible pumps, magnetic drive pumps, borehole pumps, self-priming pumps, diaphragm pumps depending on the application and nature of the fluid being transferred. At the same time, one of the significant contributors to higher costs in mining is again Pumping solutions. Pump maintenance and failure are substantial contributors to overhead costs in mining. Some of the reasons why machine performance of pumps can be poor in a mining environment are:

Corrosive elements

Mining Pumps deal with many volatile liquids such as water rich in emulsified brine phase, iron, sand, pyrite and more. The corrosive nature of such liquids can lead to abrasion and damage of pumping equipment.

Pumping Solids

In mining applications, most pumps are used to pump substances that are rich in solid particles which again leads to abrasion and damage that further leads to equipment downtime thus decreasing asset utilization.

Heat

Due to low levels of water in the liquid being pumped, pumping equipment often suffers damage due to overheating.

Keeping these points in mind, the Mining Industry increasingly realizes the benefits of moving to IIoT Pumping solutions. IoT solutions can not only prevent equipment downtime of pumps but can also bring numerous other advantages:

Who can Benefit from IIoT pumping Solution?

Integration of Industrial IoT with Pumps can benefit Pump Manufacturers, Pump Rental Vendors as well as Mining Companies who are the end users of such Pumps.

Benefits of IoT in Mining

Real-time Data Monitoring

Smart pumps when fitted with IIoT solutions can contribute real-time data on vital parameters such as the temperature of equipment, Water level in equipment, pressure levels, contamination, electricity consumption and more. IIoT solution enables remote tracking of such real-time data. Analysis of data by experts sitting even hundreds of miles away from the site can provide workers with actionable insights. This can be strategic not only to save costs but also for improving safety of equipment and human resources.

Predictive Maintenance

Huge amounts of data are generated and collected daily by sensors installed in IIoT solutions. Cloud-based platforms help process this data quickly and efficiently. The resultant Data and analytics can be beneficial in predicting equipment downtime, or equipment failure by detecting vital parameters such as temperature and pressure, monitoring maintenance history, weather conditions, etc. This can help predict any equipment failures as well as maintenance scheduling and spare parts reorder.

Increase Asset Utilization

Mining Industry, as well as Pump manufacturers, can ensure that the users can derive maximum utilization out of each pumping unit by integrating IIoT Software with it. IIoT helps automate several processes such as detailed reports on unit performance under various conditions. This helps save several man-hours that would have been otherwise wasted in creating such reports to improve asset utilization too. The high degree of accuracy, in terms of utilization, helps mining businesses have a better understanding of their operating efficiencies so that they can find ways to optimize asset utilization. in the long term.

Energy and Cost Benefits

Electricity costs contribute to 40% of the total cost of ownership of a pump. IIoT Pumping solutions provide equipment manufacturer as well as the user with detailed electricity and resource consumption trends. At the manufacturing end, such information can be utilized to install features in the design and functionality of the product to minimize energy consumption. For mining firms internet of things IoT integrated pumps can help save energy and operation cost because of real time data reporting.

Standardized Work process

IIoT integration helps build new and highly agile operation processes due to clear visibility and accountability of people and equipment. Operations of all pumping equipment can be precisely designed to standardize the work process to avoid time and resource wastage. Standardized workflow also helps promotes safety of people in a mine.

Pump Rentals get visibility into actual Usage

Pump Rental services can have a more comprehensive pricing model based on actual machine usage than just actual usage hours . This lets Rental services charge more accurately, based on actual time in use which is beneficial for both user and rental firm rather than just number of hours rented. Pump Rental companies also get real time analytics into data about usage which helps them helps to track wear and tear as part of a predictive maintenance Plan.

Technology Solution

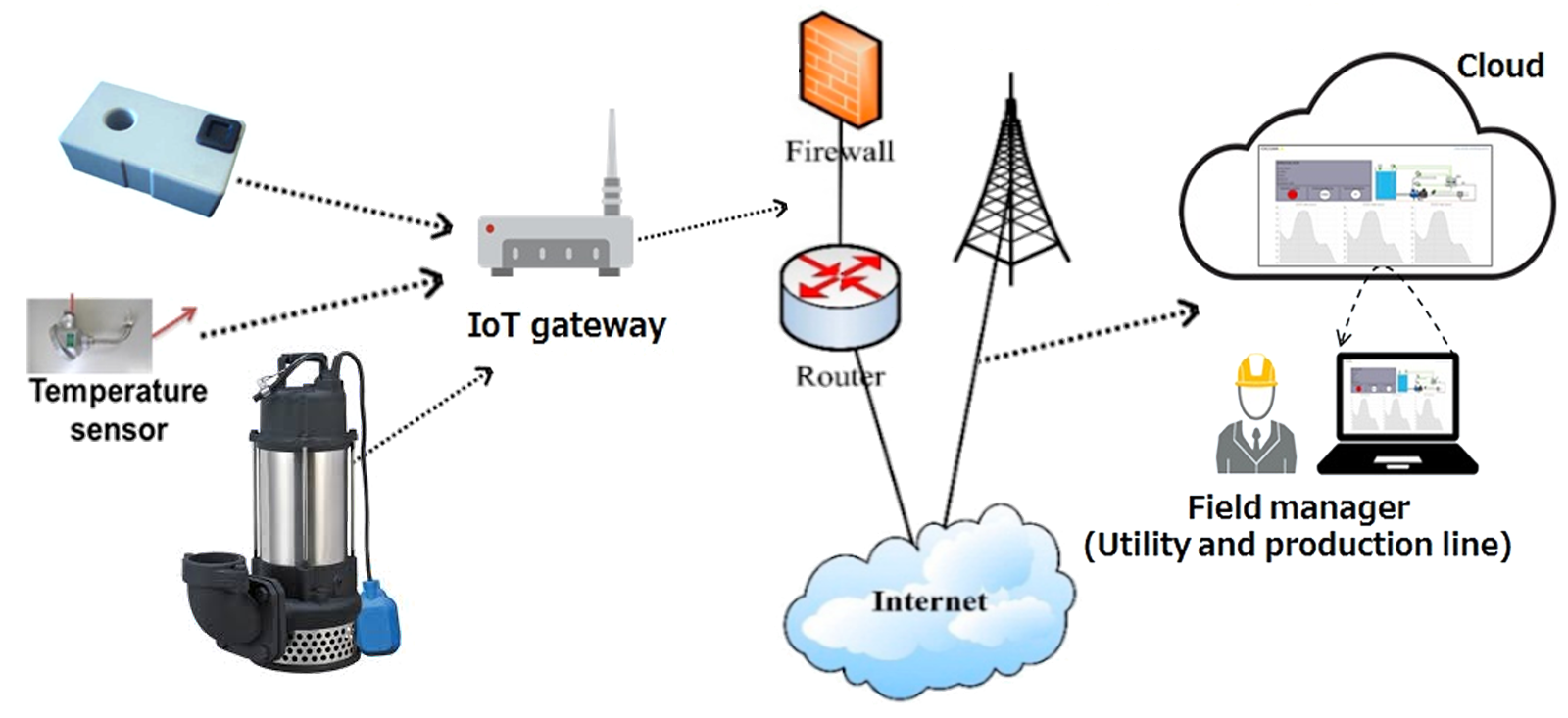

The Solution comprises of three parts:

Sensor Nodes

Sensor Nodes comprise of all the sensors which pick data from various hardware components to provide insights on actual functioning of the Pump.

Voltage Sensor

Helps to identify how long the pump has run.

Temperature Sensor

Provides real time information on temperature of the pump and allows to predict of it is time for the pump to rest to avoid malfunction due to overheating.

Vibration Sensor

The data from these sensors help provide insights on whether machine components are getting damaged due to overuse or illuse.

Data Communication

All the raw data collected by the sensors once received by the route based network Coordinator is transferred to the gateway from where through GPRS Signals it is then brought to RIMS.

Real Time Information System or RIMS

This comprises of the server part and the User Interface section.

Server Section

The Router, Knowledgebase, Data Warehouse are all part of the Server section. This is where the data gets processed and sorted.

UI section

The User Interface section is finally where all stakeholders can access the relevant data over mobile apps, Web app and more for remote operations.

With so many advantages it is only a matter of time that IIoT smart pumps become more commonplace in the mining industry. According to a research, the Internet of Things (IoT) will play a critical role in helping mining businesses to increase the level of automation and improve production efficiency, enabling them to compete with rivals operating in lower cost markets. 41% of mining firms reported that they would use IoT to increase the automation of business processes, and 44% said that it would help them to identify cost savings and efficiency opportunities.

Keeping these figures in mind Mining Pump manufacturers can tap a relatively untapped sector of the market by collaborating with software solution providers to create IIoT Pumping Solutions for Mining industry. To know more about how such software can be developed, you could drop us a message here.